Dr Richard Bowman is spearheading the creation of an open-source, 3D-printed microscope that’s able to be adapted for use in labs, schools, and the home. He was inspired by his time as a Research Fellow in the NanoPhotonics Centre at the University of Cambridge, where an early attempt at such a project was falling short because most of the mechanism was based on linear bearings and metal rods.

“The bulk of the components weren’t printable and I became curious as to how much of a microscope’s mechanism you could print,” he says. “My first version had basic focus control and an extension tube for a Raspberry Pi Camera Module to turn the stock webcam lens into a basic, but functional, microscope objective lens.” The aim is to create an easily replicable scientific instrument.

Time to focus

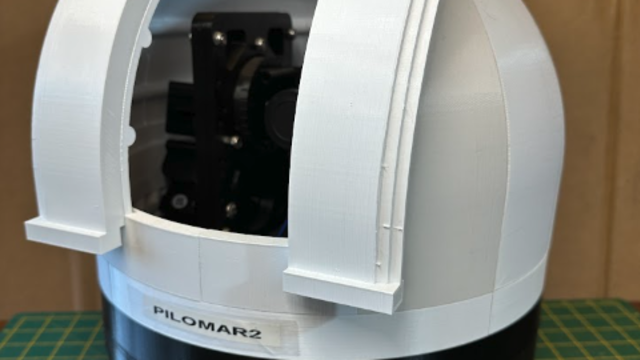

Initially, Richard sought an ideal way of moving a sample around and picking a region to view. Rather than use sliding rails which require precise machining to be smooth, the eventual design was based on the flexibility of plastic: samples are placed on a table with bendable legs that allow for controlled focus and movement on the X and Y axes.

“It uses some fairly simple geometry to convert flexible hinges into linear motion,” explains Dr Joel Collins, who later joined the project at its home at the University of Bath. “It also means we can achieve really fine sample manipulation of tens of nanometres, for orders of magnitude cheaper than most commercial microscopes.”

Unlike traditional microscopes, the project uses an upside-down design. The camera is at the base and the viewing lens is above with the light source at the top. It makes the microscope more stable. “You can arrange things so the sample is consistently close to being in focus when you place it on the microscope’s stage, which is nice,” Richard says.

Such work has helped to keep costs down. As a consequence, a student group that became WaterScope saw its potential for cheaply identifying early-stage bacterial contamination in water. Another student project demonstrated how it could be produced in Tanzania by STICLab. This led to a study which found the microscope could be used for malaria diagnosis.

Lighting the way

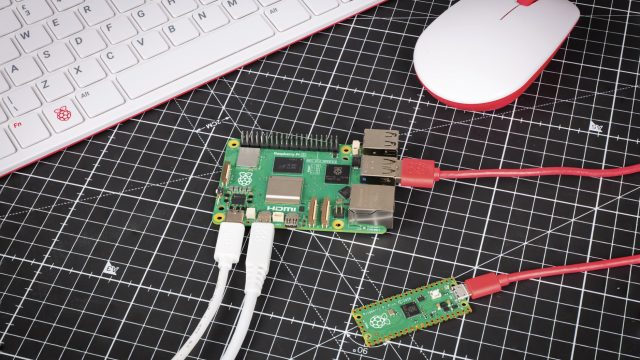

In creating the project, Richard’s team has benefited from Raspberry Pi’s bustling community. “There are great libraries for interacting with physical hardware, such as picamera and GPIO Zero,” says Joel.

“We created an HTTP API in Python and a graphical client in JavaScript that are both served by a Raspberry Pi,” he continues. “Since we have a full, powerful Linux machine in the microscope, we have many new ways to interact with the software.”

It’s possible to create an offline, standalone microscope with a fully featured interface. “If you connect it directly to your laptop via Ethernet, you can control it ‘headless’ like that, or you could have a fleet of microscopes connected to a LAN, and our software will discover all the nearby microscopes and let you control them all from a single machine,” reveals Joel.

There no doubting its impact. OpenFlexure Microscopes have been recorded on every continent, including Antarctica. The biggest challenge, however, is documentation and communication. Richard says: “Building a piece of hardware is more involved than installing pre-built software and I have a new respect for anyone who works at IKEA – their instructions must have been so carefully tested and optimised.”